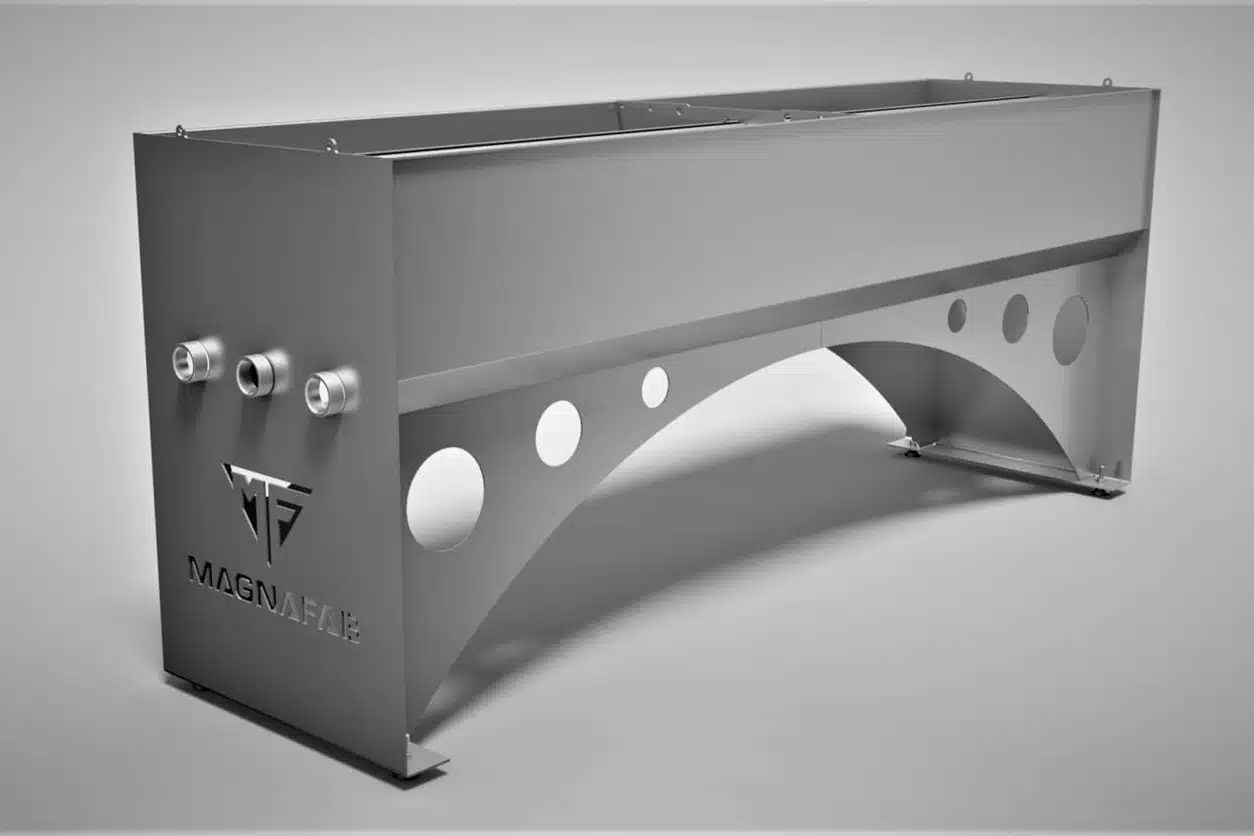

Magna Fab’s plate processing department provides high definition plasma cut parts to fabricators and manufacturers throughout the Nation. Magna Fab utilizes the most recent technology from manufactures like Messer and Ermaksan to provide high tolerance parts with a quick turnaround time.

Plasma Capabilities and Tolerances

- *96” x 288” effective cutting surface

- XPR300 X-Definition Plasma System

- Pierce up to 1.50” mild steel

- Vented Water Injection System for superior edge finish on stainless steel up to .500”

- True Hole Technology

- Marking and Etching

- .0312” Tolerance

- Multi Sheet Discounts

- .125” to 1.50” thickness on mild steel

- .125” to 1” thickness on stainless steel

- .125” to .75” thickness on Aluminum

See Our Other Capabilities

Industries Served

Our industrial fabrication customers include engineering firms, general contractors, industrial, OEM’s, to name a few. Servicing industries in food & beverage, plastic, energy, forestry, chemical, mining, structural steel, aerospace, oil & gas plants, and many others. We strive daily to distinguish ourselves as one of the premier industrial fabrication firms in the nation.

Food & Beverage

Manufacturing

Oil, Gas & Petroleum

Pharmaceuticals

Pulp & Paper

Packaging

Technology & Semiconductor

Plastics/Poly

Aerospace

Energy

Forestry & Timber

Chemical Plants

Paint & Polymers

Consumer Goods

Mining

Contact Us for a Quote

Our primary focus is on Safety, Integrity & Quality. Contact us today with your largest & toughest projects and let us show you the Magna Fab difference!